|

Introduction:

Nonlinear simulations

for structures under disasters have been widely focused on in recent years. However, precise modeling

for the nonlinear behavior of reinforced concrete (RC) shear walls, which are

the major lateral-force-resistant structural member in high-rise buildings,

still has not been successfully solved. As the cross section of the shear wall

member is much bigger than that of the beam and column member, its deformation

behavior under the lateral load is more complicated and the research has focused

on the nonlinear analysis model for shear wall at home and abroad until now.

In this paper, based on the principles of composite material mechanics, a multi-layer

shell element model is proposed to simulate the coupled in-plane/out-plane bending

or the coupled in-plane bending-shear nonlinear behaviors of RC shear wall.

At the element level, the model uses the shell element that is made up of multiple

layers with different thickness and different material models (concrete or rebar)

are assigned to various layers. Since the model relates the nonlinear behaviors

of the shear wall element to the constitutive relations of concrete and steel

directly, it

has many advantages in the description of the actual complicated nonlinear behaviors.

In the nonlinear analysis for the concrete structures, the constitutive relation

of the concrete has great effect on the analysis results. Although the traditional

elasto-plastic-fracture constitutive model for concrete is efficient, it does

not give satisfying performance for concrete under complicated stress condition.

So at the material constitution level, a novel concrete constitutive model,

referred as microplane model, which is originally proposed by Bazant et al.,

is developed to provide a better simulation for concrete in shear wall under

complicated stress conditions and stress histories. In order to validate the

capacity of the proposed shear wall model, three shear walls with different

nonlinear behaviors under given load cases were taken as examples. Pushover

analysis and static cyclic loading analysis were carried out on these shear

walls with the proposed shear wall model to illustrate the capacity

of the proposed model.

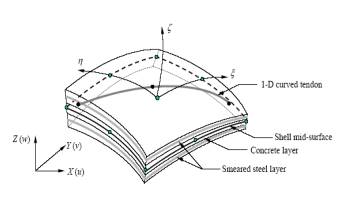

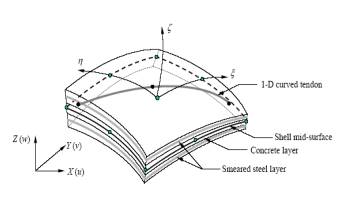

Multi-layer

shell element

The proposed

multi-layer shell element is based on the principles of composite material mechanics and it can simulate the coupled in-plane/out-plane bending

and the coupled in-plane bending-shear nonlinear behaviors of RC shear wall. Basic principles of multi-layer shell element

are illustrated by Figure 1. The shell element is made up of many layers with different thickness.

And different material properties are assigned to various layers. This means that the rebars are smeared into one layer

or more. During the finite element calculation, the axial strain and curvature

of the middle layer can be obtained in one element. Then according to the assumption

that plane remains plane, the strains and the curvatures of the other layers

can be calculated. And then the corresponding stress will be calculated through

the constitutive relations of the material assigned

to the layer. From the above principles, it

is seen that the structural

performance of the shear wall can be directly connected with the material constitutive

law.

|

|

|

Figure 1: Multi-layer shell

element

|

|

|

|

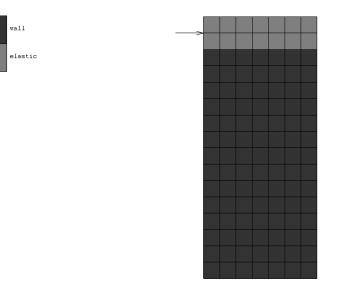

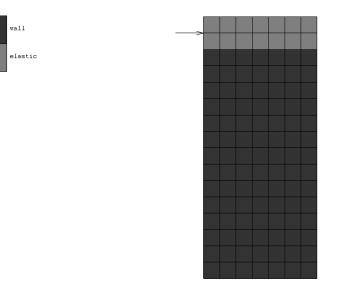

Figure 2: Settings of the rebar layers

|

The constitutive

model of the rebars is set as the perfect elasto-plastic model.

Because the rebars in different directions are smeared into one layer, so if

the ratios of the amounts of the distributing rebars to the concrete in the

longitudinal direction and transverse direction are the same, the rebar layer

can be set as isotropic. But if the ratios in the two directions are different,

the rebar layer should be set as orthotropic with two principal axes as shown in Figure 2. And in different principal axis, the stiffness is set different according

to the ratio of the amount of rebars to concrete to simulate longitudinal rebars

and transverse rebars respectively. The constitutive model of the concrete is

the microplane model which will be illuminated in

detail in the next section.

Since the model

relates the nonlinear behaviors of the shear wall element to the constitutive

relations of concrete and steel directly,

it has many advantages in the description of the actual complicated nonlinear

behaviors as compared with the existing equivalent-beam model, equivalent-truss

model and the multi-component-in-parallel model for shear wall[1].

Microplane

Constitutive Model for Concrete

Concrete is a kind of brittle-plastic

material and its relation between the stress and strain under the multi-axial

loads is very complicated, so in the nonlinear analysis for the concrete structures,

the constitutive model of the concrete has great effect on the analysis results.

Usually the precision and the validity of the shear wall model is mainly decided

by the precision and the validity of the constitutive model for concrete. The

traditional elasto-plastic-fracture constitutive models for concrete are macroscopic

models. Although great success has been reached in the past, the macroscopic

models now seem to have entered a period of diminishing returns, in which a

great effort yields only little improvement[2]. When the concrete

is under complicated stress condition, these models often caní»t give satisfying

performance for the concrete material. So at the material constitution level,

a novel concrete constitutive model, referred as micro-plane model, which is

originally proposed by Bazant et al.[5], is introduced in the proposed

shear wall model and this is achieved by developing the subroutine based on

MSC.Marc.

As one kind of the micromechanics

models, microplane model considers the microstructure of the material.

In the microplane model, a set of

planes of any orientations in the material microstructure called as the microplane

are referred. And the constitutive law is formulated in terms of vectors rather

than tensors, as a relation between the stress and strain components on these

microplanes. By integrating over the all the spatial directions, the microplane

model can satisfy the tensor invariant requirement automatically on the macroscopic

and conceptual simplicity is achieved. Due to the research work of P. Bazant

et al.[2,3,4,5], there have been much progress on microplane model

during the last 20 years. In the first version, the microplane model of concrete

was only devised for tensile fracturing, but now it has been updated to the

fourth version which can characterize the complicated nonlinear triaxial behavior

as well as the deformation behavior under the cyclic load. The results of the

numerical analysis for basic loading types with the microplane model have been

compared with many actual test results and it is shown that microplane models

can characterize the responses of concrete under different loading types[2].

Demonstration

cases

In order to

validate the capacity of the proposed shear wall model, three shear walls were

selected as the demonstration models. Pushover analysis and static cyclic

loading analysis were carried out on these shear walls with the proposed shear

wall model.

For the shear

wall, the lengths in two directions in the wall plane are both much larger than

the thickness of the wall. This is much different from the beam and column members,

and it will lead to bending deformations as well as shear deformations which

usually caní»t be neglected at the same time when the wall is under lateral load

in plane. These shear deformations in the wall plane have an important effect on the failure type of the wall and this complicated behavior causes the nonlinear

analysis of the shear wall become much more difficult than the beam element

directly. Because the shear span ratio of the wall is a main factor which affects

the shear deformation behavior, case 1 and case 2 will simulate the coupled in-plane bending-shear nonlinear behaviors of RC shear wall with different

shear span ratios respectively. And case 3 simulates the out-plane bending behaviors of RC shear

wall. Figure 3 shows

the finite element model in

case 1, and the finite element model for case 2 and case 3 are similar to case 1.

Figure 3: Finite element model

in case 1

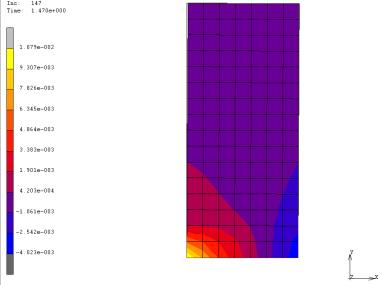

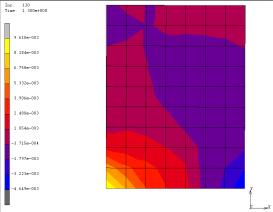

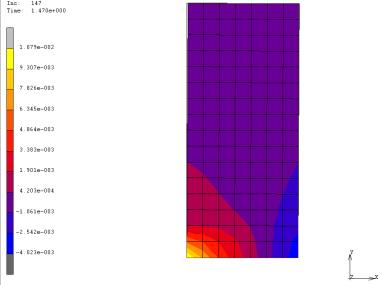

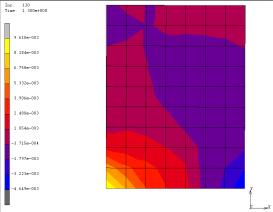

Case 1:

The shear span ratio of the shear

wall in this case is 2. For pushover analysis, the in-plane lateral load increased

by step is only applied at the top of the wall. Besides, static cyclic loading

process is also analyzed. In both the two analysis, the vertical load with the

axial force ratio of 0.2 is applied in advance at the top of the wall. The load-displacement

curve for pushover is plotted in Figure 4. Besides, the contour of the principal

major strain at the state with the peak load in pushover is plotted in Figure

6.

From Figure 4, it can be seen that

the utmost loading capacity of the shear wall is about 170kN with the displacement

of about 7mm. And Figure 6 shows that at this time, quite a lot of concrete

elements at the bottom had cracked and most tensile rebars had yielded. After

that, as the crack expanded, the compressive area was getting smaller and smaller,

which caused the loading capacity drop. It can be concluded that the failure

type of the wall in this case is mainly in-plane bending failure and shear deformation

doesní»t play an important part in the response of the shear wall.

Displacement of the shear wall along

the height at different stages in pushover is shown in Figure 5, indicating

that the shape of lateral displacement is of bending type. So the deformation

behavior of shear wall structure is clearly illustrated here.

|

|

|

|

Figure 4: Load-Displacement

curve for pushover

|

Figure 5: Displacement

along the height at different stages in pushover

|

|

|

|

Figure 6: Contour of the

principal major strain at the state with the peak load in pushover

|

|

|

|

Figure 7: Load-Displacement

curve for cyclic loading

|

Load-Displacement

curve for cyclic loading is plotted in

Figure 7 and the pinch effect is shown in it.

This reflects the actual response characteristics of the shear wall under cyclic

load clearly. Besides, exterior envelope of the load-displacement curve has

entered the softening part, which indicates that the microplane model can simulate

the damage accumulation of shear wall during the cyclic loading process precisely.

This is very important for the performance-based design of structures under

disaster loads.

Case 2:

The shear span ratio of the shear

wall in this case is 1, therefore this wall belongs to the type of short wall

and the in-plane shear failure always occurs in this type of walls.

The load-displacement curve is shown

in Figure 8 and the curve of the same relation in case 1 is also shown in Figure

8 for a comparison. It can be seen that the stiffness and the loading capacity

of the wall in case 2 are much larger than that in case 1 because the shear

span ratio has affected the response characteristic of the shear wall under

the lateral load. Similarly to case 1, the contour of the principal major strain

at the state with the peak load is plotted in Figure 9 to show more details

about the failure type of the wall. In fact, Figure 9 shows that at state of

the maximum loading capacity, a compressive column had formed in the diagonal

direction of the wall. After that, the concrete of the diagonal compressive

column was crushed and quitted the loading gradually, which caused the loading

capacity of the wall drop. But this process is more brittle than the descending

process in case 1. This can be proved by comparing the descending part of the

two curves in Figure 8. This is a typical in-plane shear failure process of

shear wall. Obviously, shear deformation plays an important part in the response

of the shear wall in this case and the shear failure process has much more brittleness

than the bending failure process.

|

|

|

|

Figure 8: Load-Displacement

curve for pushover

|

Figure 9: Contour of the

principal major strain at the state with the peak load in pushover.

|

|

|

|

Figure 10: Load-Displacement

curve for cyclic loading

|

In Figure 10, the pinch effect can

still be seen in the load-displacement curve for cyclic loading. And similarly

to Figure 7, exterior envelope of the load-displacement curve has entered the

softening part because of the damage accumulation of shear wall during the cyclic

loading process. But the exterior envelope of the load-displacement curve in

case 2 is steeper than case 1 because the shear failure process has much more

brittleness than the bending failure process

Case 3:

In the actual

shear wall structures, the shear walls are laid in both longitudinal and transverse

directions. When the lateral load is applied to structure in one direction,

the response of the wall with the plane in the same direction will present the

coupled in-plane bending-shear nonlinear behavior just as in the above case 1 and case 2. But the wall with the plane perpendicular

to the loading direction will bend out of the loading plane and present the

out-plane bending behavior. This must be considered in the finite element analysis

for shear wall structures.

In case 3, the geometric model is

the same as in case 1. To study the out-plane bending behavior of shear wall,

the out-plane lateral load increased by step is applied at the top of the wall,

and the vertical load with different axial force ratios is applied in advance

at the top of the wall.

Figure 11 shows the relation between the lateral load

and the lateral displacement at the top of the wall under different axial forces

studied. Because the thickness of the shear wall is much smaller than the height,

the out-plane bending behavior of the shear wall is very similar to the bending

behavior of the 1-D beam element. This can be proved from Figure 11.

Obviously, the program can obtain the softening out-plane

bending behavior of the wall. Besides, the plot showing the relation between

the maximum moment Mmax and corresponding axial force ratio in Figure

12, indicates accords with the existing theory[6] as well. From these

analysis results, it can be concluded that the proposed multi-layer shell element

model with the microplane constitutive models for the concrete does well in

simulating the out-plane bending behavior of the shear wall under different

axial forces.

|

|

|

|

Figure 11: Load-Displacement

curves under different axial force ratios in case 3

|

Figure 12: Relation between different axial force ratios and maximum

bending moments

|

Conclusion

The proposed

multi-layer shell element model

based on the principles of

composite material mechanics relates the nonlinear behaviors

of the shear wall element to the constitutive relations of concrete and steel

directly, and therefore it has many advantages in the description of the actual complicated

nonlinear behaviors. And at the material constitution

level, a novel concrete constitutive model, referred as micro-plane model

is introduced to provide a

better simulation for concrete in shear wall under complicated stress conditions

and stress histories. The simulation results show

that the multi-layer shell element model can correctly simulate the coupled in-plane/out-plane

bending failure for tall walls and the coupled in-plane bending-shear failure

for short walls. And with micro-plane concrete constitutive law, the cycle behavior

and the damage accumulation of shear wall can be precisely modeled, which is

very important for the performance-based design of structures under disaster

loads.

|