|

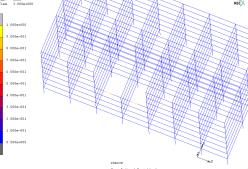

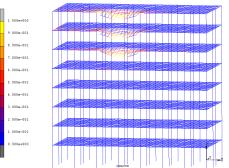

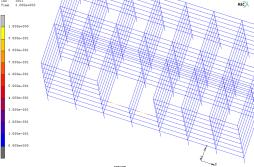

3.3 Slabs modeling

In order to study the influence

of slabs on the progressive collapse behavior of RC frames, the numerical models of the frame with and without slabs are compared:

Model A: Frame model with columns and beams

only;

Model B: Frame model including columns, beams

and slabs. When progressive collapse happens, slabs are usually in large deformation

stage, and therefore, the bending bearing capacity of slabs can be ignored

comparing with their suspending capacity. So in this paper, the reinforcement

in slabs is modeled with truss elements to consider the tensile effect of

rebars, and the concrete in slabs is not taken into account. And moreover,

when tensile strain of reinforcement reaches 10%, the reinforcement is considered

to be broken, and then the procedure will delete it automatically. Thus, the

contribution of slabs is conservatively considered by means of this method.

4 Analysis

procedure

4.1 Load case

According to the specification in DoD2005 [2], the following factored load combination is applied

to the entire structures for nonlinear dynamic analyses:

1.2Gk£«0.5Qk£«0.2Wk

(2)

where, Gk =standard value of dead load; Qk =standard

value of live load; Wk =standard value of wind load.

4.2 Analysis

procedure

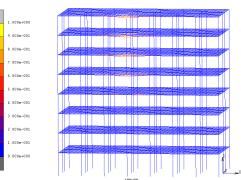

Alternate Path (AP) method based on the dynamic nonlinear analysis is

used in this paper to analyze the progressive collapse resistance capacity

because of its high accuracy. In AP method, one vertical load-bearing element

is removed instantaneously from Model A and Model B in every load case to

check the bridge over capacity of the residual structures. The columns are

near the middle of the short side, near the middle of the long side and at

the corner of the building at each floor are removed. Besides, an internal

column at ground floor is also removed, as shown in Figure 9.

|

|

|

Fig.9 Column removal locations

|

According to the DoD2005

[2], the beams are considered to be failed (or collapsed)

when their deflections reach 10% of their spans or the tensile strain of reinforcement

in them exceeds 10%. If collapse area exceeds the value specified in DoD2005 [2], the structure will be considered that

its progressive collapse resistance is insufficient and the collapsed part

need be strengthened. Both the results of collapse resistance and strengthening

reinforcement of Model A and Model B are compared to analysis the effect of

slabs in collapse process.

5 Results

5.1 Collapse

resistance capacity

The results of simulations

for collapse of Model A and Model B are listed in Table 1. It can be indicated

that Chinese typical RC frames have insufficient collapse resistance. For

the columns in different stories located at the same planar position, the

columns in higher stories have more collapse possibility, as shown in Table

1, because the higher floor the removed column

Table 1 the

results of simulations for collapse of Model A and Model B

|

Floor

|

Column removal location

|

Model A

|

Model B

|

|

ground

|

Corner

|

survive

|

survive

|

|

Long side

|

survive

|

survive

|

|

Short side

|

survive

|

survive

|

|

Internal

|

survive

|

survive

|

|

1 th

|

Corner

|

survive

|

survive

|

|

Long side

|

survive

|

survive

|

|

Short side

|

survive

|

survive

|

|

2 th

|

Corner

|

collapse**

|

survive **

|

|

Long side

|

survive

|

survive

|

|

Short side

|

survive

|

survive

|

|

3 th

|

Corner

|

collapse

|

collapse

|

|

Long side

|

survive

|

survive

|

|

Short side

|

survive

|

survive

|

|

4 th

|

Corner

|

collapse

|

collapse

|

|

Long side

|

collapse **

|

survive **

|

|

Short side

|

survive

|

survive

|

|

5 th¡«7 th

|

Corner

|

collapse

|

collapse

|

|

Long side

|

collapse

|

collapse

|

|

Short side

|

survive

|

survive

|

|