|

5. Theoretical analysis

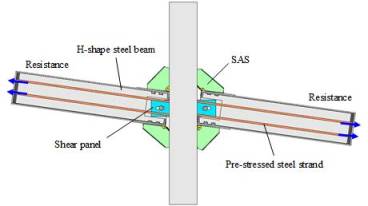

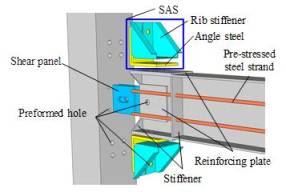

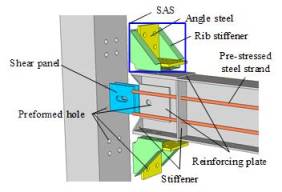

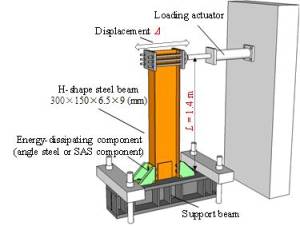

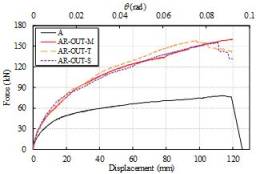

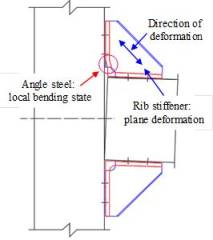

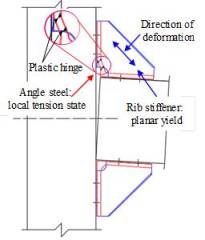

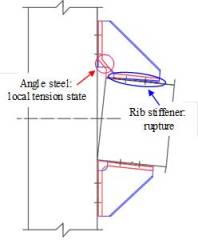

The

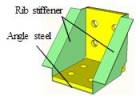

SAS component is a new type of energy-dissipating component. Because Specimen

AR-OUT-S exhibited the highest stability and sufficient strength and initial

stiffness, the SAS component discussed hereafter is similar to Specimen AR-OUT-S.

The yield bending moment of the SAS connection can be calculated by the superposition

of the bending moments provided by the angle steel and the rib stiffener,

respectively. The initial stiffness of the SAS connection can be calculated

through the same superposition method. Note that the design methods of the

angle steel connection have been widely studied by many researchers [38-41].

Therefore, these research outcomes can be used in this work, while the design

method of rib stiffeners needs to be developed.

5.1. Parameter calibration

for the model of angle steel connection

Many

studies have shown that the three-parameter power model proposed by Kishi

and Chen [41] can accurately describe the behavior of angle steel connections

[38-40]. Therefore, the Kishi¨CChen power model was adopted to predict the

moment¨Crotation relations of angle steel connection

in this work. The Kishi¨CChen power model contains three key parameters: initial

stiffness  ,

ultimate moment

,

ultimate moment  ,

and shape parameter

,

and shape parameter

.

The equation is as follows:

.

The equation is as follows:

| |

|

(1)

|

in

which  ,

M

A and q are moment and relative rotation in the connection, respectively. ,

M

A and q are moment and relative rotation in the connection, respectively.

Kishi and Chen

[41] proposed the computational equations of the initial stiffness

and the ultimate moment

and the ultimate moment

. The shape

parameter nA is determined through

the least-squares fitting between the predicted moments and the

experimental ultimate moments. Note that this method can effectively predict

the moment¨Crotation relations when the moment approaches

the ultimate moment. However, the ultimate moment is significantly larger

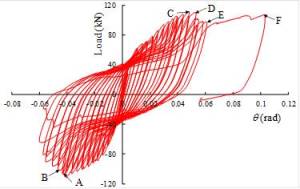

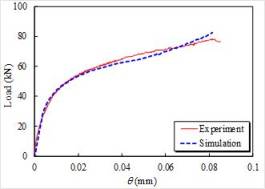

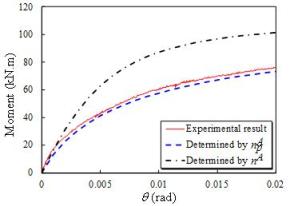

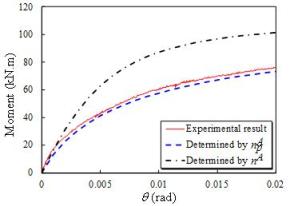

than the yield moment. The test of Specimen A shows that the moment¨Crotation

relations determined by the

shape parameter nA cannot predict the yield moment well

(Fig. 17). Therefore, to predict the yield moment of the angle steel connection

accurately, the shape parameter was recalibrated in this work by ensuring

that the predicted and experimental moment¨Crotation relations

have same energy within the specified rotation qp, and the new shape parameter is denoted as

. The shape

parameter nA is determined through

the least-squares fitting between the predicted moments and the

experimental ultimate moments. Note that this method can effectively predict

the moment¨Crotation relations when the moment approaches

the ultimate moment. However, the ultimate moment is significantly larger

than the yield moment. The test of Specimen A shows that the moment¨Crotation

relations determined by the

shape parameter nA cannot predict the yield moment well

(Fig. 17). Therefore, to predict the yield moment of the angle steel connection

accurately, the shape parameter was recalibrated in this work by ensuring

that the predicted and experimental moment¨Crotation relations

have same energy within the specified rotation qp, and the new shape parameter is denoted as

.

.

Fig. 17. Differences between nA

and  (neergy with Specimen A)

(neergy with Specimen A)

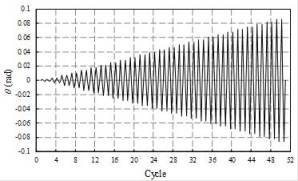

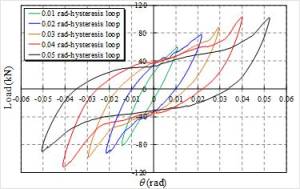

qp should be greater than the yield rotation, but it should not be

excessively large. Otherwise, it will affect the accuracy of the predicted

yield moment. The maximum acceptable story drift of the steel structure specified

in the Code for Seismic Design of Buildings (GB 50011-2010) [33] is 0.02 rad;

thus, in this work, qp

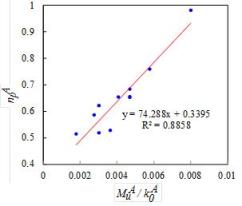

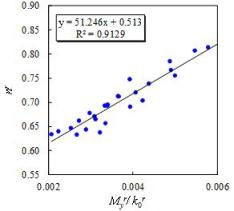

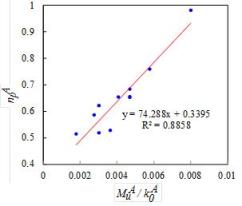

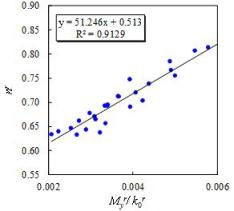

is set to 0.02 rad. Based on the data from literature listed in Table 2,

can be determined

by least-squares curve fitting (shown in Eq. (2) and Fig. 18).

can be determined

by least-squares curve fitting (shown in Eq. (2) and Fig. 18).

| |

|

(2)

|

The

yield moment of the angle steel connection MyA

is defined as follows:

| |

|

(3)

|

in which

is

the yield rotation. is

the yield rotation.

Fig. 18. Least-squares curve fitting of

Table 2

Geometrical and mechanical characteristics of monotonic loading tests

|

Specimen ID

|

Beam (mm)

|

Column (mm)

|

Top angle (seat angle)

(mm)

|

|

|

JT-07 [42]

|

H254´102´5.7´6.8

|

H153´152´5.8´6.8

|

L80´60´8 (L125´75´8)

|

0.622

|

|

JT-08 [42]

|

H254´102´5.7´6.8

|

H153´152´5.8´6.8

|

L80´60´8 (L125´75´8)

|

0.520

|

|

TSC-M [43]

|

H300´150´7.1´10.7

|

H300´150´7.1´10.7

|

L120´120´12

|

0.529

|

|

TA-4 [44]

|

H250´125´6´9

|

H350´175´6´9

|

L140´90´12

|

0.655

|

|

JD1 [45]

|

H300´300´8´12

|

H200´200´12´12

|

L110´110´12

|

0.760

|

|

JD2 [45]

|

H300´300´8´12

|

H200´200´12´12

|

L140´140´16

|

0.982

|

|

W00 [46]

|

H400´200´8´13

|

H408´408´21´21

|

L150´100´12

|

0.516

|

|

ZRBA2-1 [47]

|

H298´149´5.5´8

|

H300´300´10´15

|

L125´125´12

|

0.685

|

|

ZRBA2-2 [47]

|

H298´149´5.5´8

|

H300´300´10´15

|

L125´125´12

|

0.654

|

|

ZRBA2-3 [47]

|

H298´149´5.5´8

|

H300´300´10´15

|

L125´125´12

|

0.656

|

|

F1 [48]

|

H300´250´8´12

|

H400´300´10´14

|

L160´160´10

|

0.587

|

Taking Specimen

A as an example, the comparisons of the predicted moment¨Crotation curves (q ¡Ü 0.02 rad)

determined by nA and  are shown in Fig. 17.

The results show that

are shown in Fig. 17.

The results show that  can better determine

moment¨Crotation relations of angle steel connection when q ¡Ü 0.02 rad.

In other words, the yield moment of angle steel connection

can be predicted more accurately by

can better determine

moment¨Crotation relations of angle steel connection when q ¡Ü 0.02 rad.

In other words, the yield moment of angle steel connection

can be predicted more accurately by

.

.

5.2. Theoretical calculating

method of rib stiffeners

5.2.1. Initial

stiffness provided by rib stiffeners

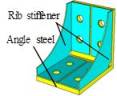

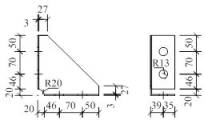

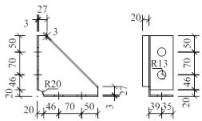

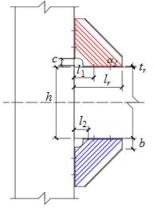

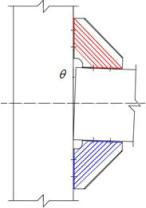

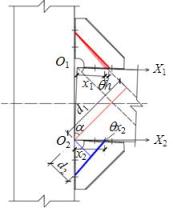

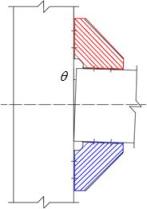

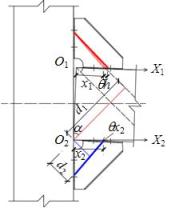

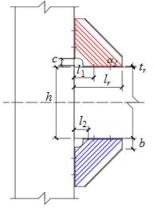

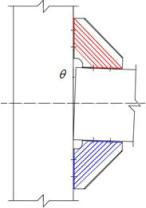

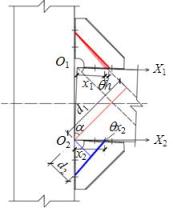

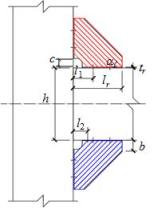

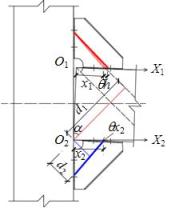

Based on the

FE results, the effective stress area of rib stiffeners can be simplified

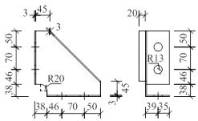

as a set of strips with a specific angle a. Fig. 19(a) shows the equivalent stress

area of rib stiffeners for the calculation of initial stiffness, in which

the red area represents tension and the blue area represents compression. Fig. 19(b) shows the deformation mode of rib stiffeners

with a connection rotation q. Fig. 19(c) shows the deformation of

simplified strips with a connection rotation q. Fig. 19(d)

shows the equivalent force model for the calculation of initial stiffness

provided by rib stiffeners.

|

|

|

|

|

|

(a) Effective stress area

|

(b) Deformation mode of connection

|

(c) Deformation mode of simplified

strips

|

(d) Equivalent force model

|

Fig. 19. Schematics for the calculation of the

initial stiffness provided by the rib stiffeners

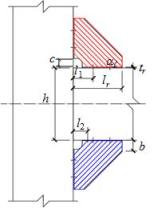

(1) For tensile

rib stiffeners:

The strain of

tensile strips is

| |

, ,

|

(4)

|

where

is the coefficient accounting for

the nonuniform stress of tensile strips when calculating the initial stiffness,

h is the height of beam, x1 is a variable which is

the distance between the strip and the beam end, a is the inclination angle of strips,

and the recommended value is 45º.

is the coefficient accounting for

the nonuniform stress of tensile strips when calculating the initial stiffness,

h is the height of beam, x1 is a variable which is

the distance between the strip and the beam end, a is the inclination angle of strips,

and the recommended value is 45º.

The cross-sectional

area of tensile strips is

| |

, ,

|

(5)

|

where tr is the thickness of the rib stiffeners.

The arm of force

of tensile strips to Point O2 is

| |

. .

|

(6)

|

The moment provided

by a tensile rib stiffener to Point O2 is

|

, ,

|

(7)

|

where lr is

the height of the rib stiffener, l1 is the minimum distance between the bolt hole edge and

the beam end (Fig. 19), and Er is the modulus of elasticity

of the rib stiffeners.

Consequently,

the initial stiffness provided by a tensile rib stiffener to Point O2

is

|

. .

|

(8)

|

(2) For compression

rib stiffeners:

The strain of

compression strips is

| |

, ,

|

(9)

|

where

is the coefficient accounting for

the nonuniform stress of compression strips when calculating the initial stiffness,

and x2

is a variable that is the distance between the strip and the beam end.

is the coefficient accounting for

the nonuniform stress of compression strips when calculating the initial stiffness,

and x2

is a variable that is the distance between the strip and the beam end.

The cross-sectional

area of the compression strips is

| |

. .

|

(10)

|

The arm of force

of the compression strips to Point O2 is

| |

. .

|

(11)

|

The moment provided

by a compression rib stiffener to Point O2 is

|

, ,

|

(12)

|

where l2 is the distance between the beam end and the

strip closest to the beam end (Fig. 19).

The initial

stiffness provided by a compression rib stiffener to Point O2

is

|

. .

|

(13)

|

Take a = 45º, the initial stiffness provided

by the rib stiffeners is determined as follows:

|

|

(14)

|

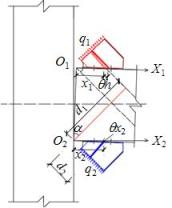

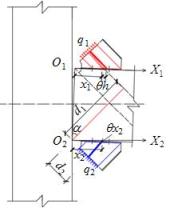

5.2.2. Yield

moment provided by rib stiffeners

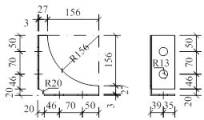

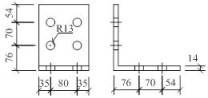

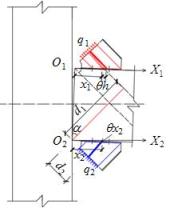

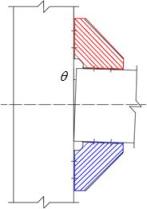

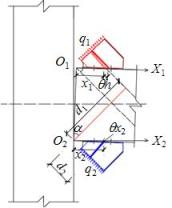

The yield moment

provided by the rib stiffeners can be defined as the sum of the yield moments

provided by all the strips. The corresponding equivalent area, deformation

mode and equivalent force model for the calculation of the yield moment provided

by the rib stiffeners can be determined in Fig. 20(a-d).

|

|

|

|

|

|

(a) Effective stress area

|

(b) Deformation mode of connection

|

(c) Deformation mode of simplified

strips

|

(d) Equivalent force model

|

Fig. 20. Schematics for calculation of yield moment

provided by rib stiffeners

(1) For tensile

rib stiffeners:

The resultant

tensile force is

|

, ,

|

(15)

|

where b

and c are the dimensions of the rib stiffeners shown in Fig. 20,

is the yield strength of the rib

stiffeners, and

is the yield strength of the rib

stiffeners, and  is the coefficient accounting for

the nonuniform stress of tensile strips when calculating the yield moment.

is the coefficient accounting for

the nonuniform stress of tensile strips when calculating the yield moment.

The arm of force

of the tensile strips to Point O2 is

|

, ,

|

(16)

|

The yield moment

provided by a tensile rib stiffener to Point O2 is

|

. .

|

(17)

|

(2) For compression

rib stiffeners:

The resultant

compression force is

|

, ,

|

(18)

|

where

is the coefficient accounting for

the nonuniform stress of compression strips when calculating the yield moment.

is the coefficient accounting for

the nonuniform stress of compression strips when calculating the yield moment.

The arm of force

of compression strips to Point O2 is

|

. .

|

(19)

|

The yield moment

provided by a compression rib stiffener to Point O2 is

|

. .

|

(20)

|

Take a = 45º, the yield moment provided

by rib stiffeners is determined as follows:

|

|

(21)

|

|

| |

|

|

|

|

|

|

|

|

|

5.2.3. Coefficients

accounting for nonuniform stress determined by FE models

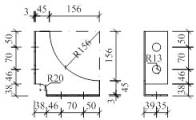

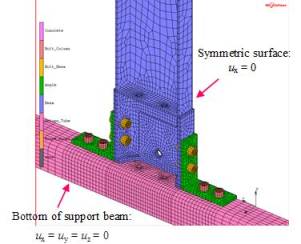

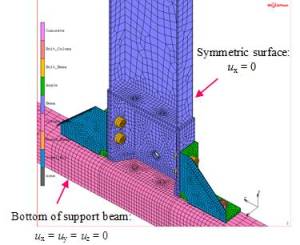

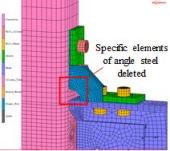

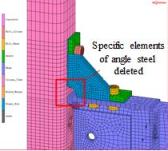

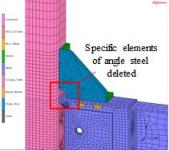

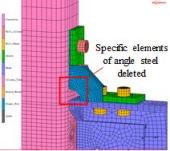

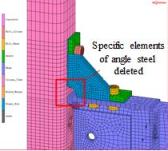

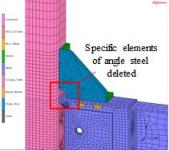

Based on the

above analysis, the initial stiffness and the yield moment provided by the

rib stiffeners can be calculated, if the coefficients

accounting for nonuniform stress (

,

,  ,

,  , and

, and

)

are determined. Due to the limited number of experiments

available, the FE model calibrated by experimental data (shown in Section

4) is adopted for the parametric analysis herein. To calculate the initial stiffness and yield moment provided by

the rib stiffeners and eliminate the influence of angle steel, the specific

elements at the corner of the angle steel in the FE model are deleted (Fig.

21).

)

are determined. Due to the limited number of experiments

available, the FE model calibrated by experimental data (shown in Section

4) is adopted for the parametric analysis herein. To calculate the initial stiffness and yield moment provided by

the rib stiffeners and eliminate the influence of angle steel, the specific

elements at the corner of the angle steel in the FE model are deleted (Fig.

21).

|

|

|

|

|

(a) lr =

0.1 m

|

(a) lr =

0.15 m

|

(a) lr =

0.2 m

|

Fig.

21.

FE models with different height of rib stiffeners

The variable

parameters in the FE model include the height of beam h

(0.3, 0.35, and 0.4 m), the thickness of rib stiffeners tr

(0.001, 0.002, 0.003, 0.004, 0.005, 0.006, and 0.007 m), the height

of rib stiffeners lr (0.1, 0.15, and 0.2 m),

and the yield strength of rib stiffeners

(235,

345, and 368 MPa). The definition of the

variable parameters (h, tr,

and lr) are shown in Fig. 19(a). The FE models with different heights of rib stiffeners are

shown in Fig. 21. The simulation results show that if tr/ta

(ta is the thickness of the angle steel) is too large,

it will result in the deformation of the angle steel, which will reduce the

energy-dissipating capacity. In contrast, if tr/ta

is too small, the rib stiffeners have little contribution. Consequently, after

a series of parametric discussions, tr/ta

should meet the following criterion:

(235,

345, and 368 MPa). The definition of the

variable parameters (h, tr,

and lr) are shown in Fig. 19(a). The FE models with different heights of rib stiffeners are

shown in Fig. 21. The simulation results show that if tr/ta

(ta is the thickness of the angle steel) is too large,

it will result in the deformation of the angle steel, which will reduce the

energy-dissipating capacity. In contrast, if tr/ta

is too small, the rib stiffeners have little contribution. Consequently, after

a series of parametric discussions, tr/ta

should meet the following criterion:

.

.

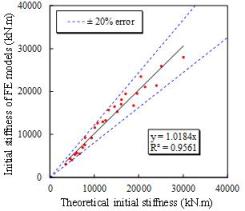

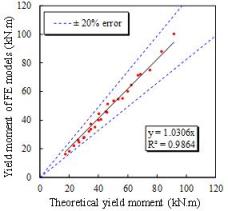

With the comparisons of initial stiffness and yield moment between

the simulation results and the computational results from Eqs. (14) and (21),

,

,

,

,

, and

, and

can be determined as follows by data fitting:

can be determined as follows by data fitting:

Substituting

,

,

,

,

,

and

,

and  into Eqs.

(14) and (21) results in

into Eqs.

(14) and (21) results in

|

and and

|

(25)

|

|

. .

|

(26)

|

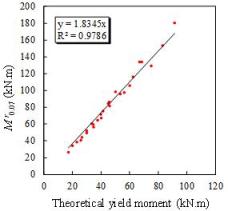

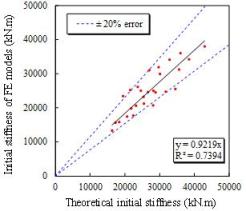

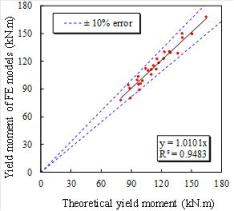

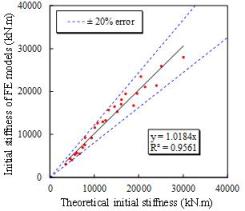

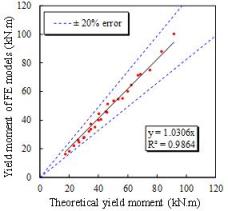

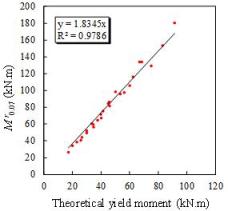

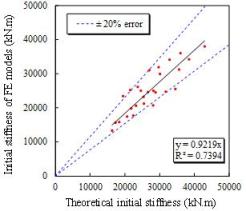

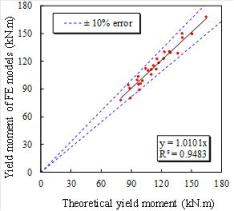

The comparisons

of the initial stiffness and yield moment between the FE results and the calculation

results from Eqs. (25) and (26) are shown in Figs. 22 and 23, respectively,

and the results show good agreement.

Fig.

22. Initial stiffness

provided by rib stiffeners

Fig.

23. Yield moment

provided by rib stiffeners

Additionally, the moment-rotation relations provided by rib stiffeners

can be defined as follows, similar to Eq. (1):

| |

, ,

|

(27)

|

where  ,

,

is the maximum moment

provided by rib stiffeners when

is the maximum moment

provided by rib stiffeners when  , and

, and  is the shape parameter of

the rib stiffeners.

is the shape parameter of

the rib stiffeners.

Because the strength provided

by some rib stiffeners will decrease when  ,

,

is taken as a basic

parameter in this work. Based on the former mentioned FE results (Figs. 24

and 25) and Eqs. (25) and (26),

is taken as a basic

parameter in this work. Based on the former mentioned FE results (Figs. 24

and 25) and Eqs. (25) and (26),  and

and

can be determined as follows:

can be determined as follows:

Fig.

24. Data fitting

for

Fig.

25. Theoretical

calculation of

| |

and and

|

(28)

|

| |

. .

|

(29)

|

Consequently,

can be determined as

follows:

can be determined as

follows:

| |

|

(30)

|

5.3. Evaluation of initial

stiffness and yield moment provided by SAS

Based on the above analysis, the calculation method of the initial

stiffness and the yield moment provided by SAS can be determined as follows:

The initial stiffness provided

by SAS is the sum of that provided by the angle steels and the rib stiffeners:

|

|

(31)

|

Note that the stiffness of SAS will significantly decrease after

the yield of the rib stiffeners. Therefore, it is assumed that SAS will reach

the yield point when the rib stiffeners yield, and, consequently, the yield

moment provided by SAS can be determined as follows: (1) determine the yield

moment provided by the rib stiffeners  through Eq. (26); (2)

determine the yield rotation

through Eq. (26); (2)

determine the yield rotation  of the rib

stiffeners through Eq. (30); and (3) determine the yield moment provided by the angle steel

of the rib

stiffeners through Eq. (30); and (3) determine the yield moment provided by the angle steel

through Eq. (3). Subsequently,

the yield moment provided by SAS can be determined as follows:

through Eq. (3). Subsequently,

the yield moment provided by SAS can be determined as follows:

|

|

(32)

|

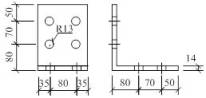

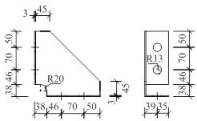

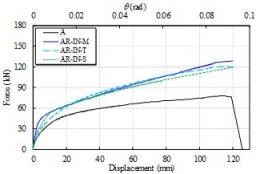

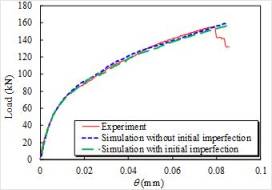

To validate

the above equation, a series of FE models of SAS were established, and the

variable parameters in the FE models included the following: the thickness

of the angle steel ta = 14 mm; the other parameters of angle

steels, the same as the FE model shown in Fig. 14(a); the height of beam h

(0.3, 0.35, and 0.4 m); the thickness of rib stiffeners tr

(0.002, 0.003, and 0.004 m); and the height of rib stiffeners lr

(0.1, 0.15, and 0.2 m). The comparisons of the initial stiffness and

the yield moment provided by SAS between the simulation results and the calculation

results from Eqs. (31) and (32) are shown in Fig. 26 and Table 3, with

a good agreement, which proves the rationality of the calculation method proposed

in this work.

|

|

|

|

(a) Initial stiffness

|

(b) Yield moment

|

Fig.

26. Comparisons of initial stiffness

and yield moment provided by SAS between simulation and calculation results

Table 3

Comparisons of initial stiffness

and yield moment provided by SAS between the FE results and the proposed model

|

No.

|

h

(mm)

|

tr (mm)

|

lr

(mm)

|

Initial stiffness

|

Yield moment

|

|

FE results

(kN¡¤m)

|

Eq. (31)

(kN¡¤m)

|

Error

|

FE results

(kN)

|

Eq. (32)

(kN)

|

Error

|

|

1

|

300

|

2

|

100

|

1.34¡Á104

|

1.63¡Á104

|

21.4%

|

77.90

|

79.68

|

2.28%

|

|

2

|

300

|

3

|

100

|

1.57¡Á104

|

1.73¡Á104

|

10.2%

|

80.20

|

89.08

|

11.07%

|

|

3

|

300

|

4

|

100

|

1.59¡Á104

|

1.84¡Á104

|

15.4%

|

88.90

|

98.08

|

10.33%

|

|

4

|

300

|

2

|

150

|

2.34¡Á104

|

1.94¡Á104

|

-17.1%

|

94.40

|

87.07

|

-7.76%

|

|

5

|

300

|

3

|

150

|

2.53¡Á104

|

2.15¡Á104

|

-14.8%

|

99.00

|

101.33

|

2.35%

|

|

6

|

300

|

4

|

150

|

2.62¡Á104

|

2.37¡Á104

|

-9.4%

|

111.70

|

115.05

|

3.00%

|

|

7

|

300

|

2

|

200

|

1.78¡Á104

|

2.24¡Á104

|

25.8%

|

95.00

|

97.50

|

2.63%

|

|

8

|

300

|

3

|

200

|

2.13¡Á104

|

2.55¡Á104

|

19.7%

|

118.30

|

117.25

|

-0.89%

|

|

9

|

300

|

4

|

200

|

2.45¡Á104

|

2.88¡Á104

|

17.4%

|

128.90

|

136.43

|

5.84%

|

|

10

|

350

|

2

|

100

|

1.74¡Á104

|

2.07¡Á104

|

18.5%

|

90.80

|

88.46

|

-2.58%

|

|

11

|

350

|

3

|

100

|

1.99¡Á104

|

2.19¡Á104

|

9.9%

|

95.90

|

99.54

|

3.80%

|

|

12

|

350

|

4

|

100

|

2.07¡Á104

|

2.32¡Á104

|

12.1%

|

105.80

|

110.00

|

3.97%

|

|

13

|

350

|

2

|

150

|

2.50¡Á104

|

2.46¡Á104

|

-1.9%

|

99.60

|

95.86

|

-3.76%

|

|

14

|

350

|

3

|

150

|

3.11¡Á104

|

2.70¡Á104

|

-13.1%

|

115.50

|

112.27

|

-2.79%

|

|

15

|

350

|

4

|

150

|

3.20¡Á104

|

2.97¡Á104

|

-7.2%

|

130.70

|

127.82

|

-2.21%

|

|

16

|

350

|

2

|

200

|

2.08¡Á104

|

2.82¡Á104

|

35.4%

|

110.00

|

106.86

|

-2.85%

|

|

17

|

350

|

3

|

200

|

2.48¡Á104

|

3.18¡Á104

|

28.3%

|

129.30

|

129.15

|

-0.11%

|

|

18

|

350

|

4

|

200

|

3.13¡Á104

|

3.56¡Á104

|

14.0%

|

149.70

|

150.51

|

0.54%

|

|

19

|

400

|

2

|

100

|

2.32¡Á104

|

2.53¡Á104

|

8.9%

|

103.50

|

97.09

|

-6.20%

|

|

20

|

400

|

3

|

100

|

2.47¡Á104

|

2.67¡Á104

|

8.2%

|

111.10

|

110.15

|

-0.85%

|

|

21

|

400

|

4

|

100

|

2.51¡Á104

|

2.82¡Á104

|

12.6%

|

123.10

|

122.26

|

-0.68%

|

|

22

|

400

|

2

|

150

|

3.00¡Á104

|

3.01¡Á104

|

0.4%

|

112.30

|

104.22

|

-7.20%

|

|

23

|

400

|

3

|

150

|

3.41¡Á104

|

3.29¡Á104

|

-3.6%

|

130.40

|

123.12

|

-5.58%

|

|

24

|

400

|

4

|

150

|

3.61¡Á104

|

3.60¡Á104

|

-0.2%

|

150.00

|

140.65

|

-6.23%

|

|

25

|

400

|

2

|

200

|

2.56¡Á104

|

3.45¡Á104

|

34.5%

|

122.50

|

115.72

|

-5.53%

|

|

26

|

400

|

3

|

200

|

3.42¡Á104

|

3.85¡Á104

|

12.4%

|

145.50

|

140.87

|

-3.18%

|

|

27

|

400

|

4

|

200

|

3.80¡Á104

|

4.30¡Á104

|

13.1%

|

167.90

|

164.57

|

-1.98%

|

|

Average error

|

9.3%

|

|

|

-0.54%

|

|

Standard deviation

|

0.143

|

|

|

0.048

|

|