3 Optimal Design of Structural

System

3.1 Two options for

the structural system

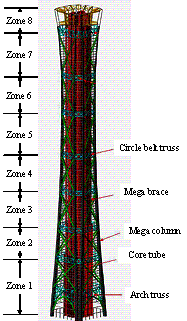

Due

to the height of the supertall building, its structural responses are more

sensitive to the lateral loads (wind and seismic loads) than those of the

ordinary frames or shear wall structures; in most cases the design of a supertall

building is dominated by the lateral stiffness (Moon, 2014). Therefore, choosing

a reasonable lateral force resisting system has a great influence on the cost

and safety of supertall buildings. CTBUH (2015b) has conducted an investigation

on the lateral force resisting systems of 75 supertall buildings constructed

between 1961 and 2010 worldwide. They include 20 framed-tube buildings, 4

bundled-tube buildings, 15 tube-in-tube buildings, 10 diagonalized buildings,

19 mega column/core tube/outrigger buildings and 7 mega column/core tube/brace

buildings. The statistics also indicate that the framed-tube, bundled-tube

and tube-in-tube structures are mainly applied in the tall buildings lower

than 90 stories. Among the 15 supertall buildings constructed between 2001

and 2010, 11 adopted the mega column/core tube/outrigger system and 3 adopted

the mega column/core tube/brace system. Conclusively, the mega structural

systems (e.g., the mega column/core tube/outrigger system and mega column/core

tube/brace system) have become the best choice for the lateral force resisting

systems of modern supertall buildings.

Consequently, the supertall building

studied herein also adopts such a mega structural system. In August 2011,

two design schemes with different lateral force resisting systems are proposed

at the preliminary design stage according to the requirement of architectural

features. The differences of these two schemes are briefly described as follows.

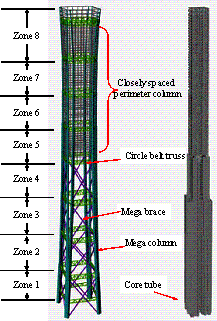

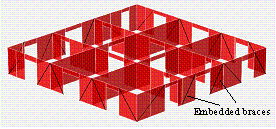

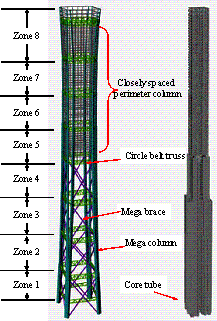

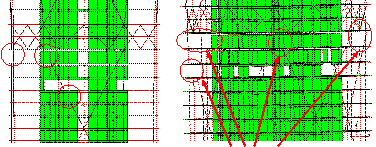

The first scheme is referred to as the

��half-braced scheme��. The lateral force resisting system at the lower four

zones involves mega columns, core tube and mega braces; while in the upper

four zones, the mega columns, core tube and outriggers are adopted as the

main lateral force resisting system, as shown in Figure 4(a). The mega columns,

located at four corners, are constructed by CFST and their cross sections

decrease along the building height. Each mega column at the corner is separated

into two columns from Zone 2 and extends to the top of the building. The mega

braces are arranged at the periphery of the building between Zone 1 and Zone

4. For the upper four zones, closely spaced perimeter columns are used instead

of mega braces. Nine circle belt trusses are arranged along the building height

at 13 to 15-story intervals. The outriggers are built between Zone 5 and Zone

8.

|

|

|

|

(a) Half-braced scheme

|

(b) Fully-braced scheme

|

Figure 4. The sketch of the

two design schemes

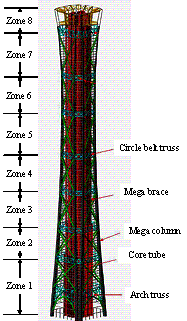

The other design scheme is referred to

as the ��fully-braced scheme�� and the main lateral force resisting system includes

mega columns, core tube and mega braces, as shown in Figure 4(b). The mega

columns are also constructed by CFST and the layout of the mega columns is

similar to the half-braced scheme except for the following two differences:

(a) Each corner has two mega columns; (b) the mega columns only extend to

the top of Zone 7. Zone 8, which is a sightseeing region, has no mega column.

The mega braces are arranged throughout the building height. The number of

circle belt trusses is reduced to eight comparing to the half-braced scheme.

The core tube of the fully-braced scheme is similar to the half-braced scheme.

3.2 Material consumption

The

fundamental vibration periods of the half-braced and fully-braced design schemes

are 7.44 s and 7.38 s, respectively. This implies that the lateral stiffness

of the fully-braced scheme is larger than that of the half-braced scheme.

The material consumption of these two schemes is compared in Table 2. Note

that both design schemes are for the preliminary design phase, therefore only

the concrete and steel consumptions of the main structural components are

calculated and compared; whereas the material consumption of non-structural

components is not considered.

Table 2. Comparison of the total

material consumption of the two design schemes

| |

Half-braced scheme

|

Fully-braced scheme

|

Relative deviation

|

|

Total mass (ton)

|

753 720

|

669 382

|

-11.19%

|

|

Concrete consumption (ton)

|

652 938

|

565 211

|

-13.44%

|

|

Steel consumption in mega

columns (ton)

|

29 074

|

23 934

|

-17.68%

|

|

Steel consumption in all

steel components (ton)

|

65 408

|

73 936

|

13.04%

|

|

Steel consumption in slab (ton)

|

6 300

|

6 093

|

-3.29%

|

|

Total steel consumption (ton)

|

100 783

|

103 963

|

3.16%

|

The comparison shows that the total material consumption (concrete

and steel) of the fully-braced scheme is 11.19% less than that of the half-braced

scheme. This is mainly because the mega columns and shear walls in the fully-braced

scheme have smaller cross sections, which results in a reduction of 13.44%

in concrete consumption. The steel consumption of the two design schemes,

on the other hand, is very similar. Specifically, the steel consumption of

the mega columns in the fully-braced scheme is 17.68% less than that of the

half-braced scheme; while the steel consumption of the mega braces increases

13.04% comparing to the half-braced scheme. Consequently, the total steel

consumption of the fully-braced scheme is only 3.16% larger than that of the

half-braced scheme. Overall, although the mega braces in the fully-braced

scheme result in a larger steel consumption, due to more uniform lateral stiffness

in the fully-braced scheme, the cross sections of other components have been

reduced and in turn resulted in a similar amount of the total steel consumption

of these two design schemes. In addition, the total mass of the fully-braced

scheme is smaller than that of the half-braced scheme.

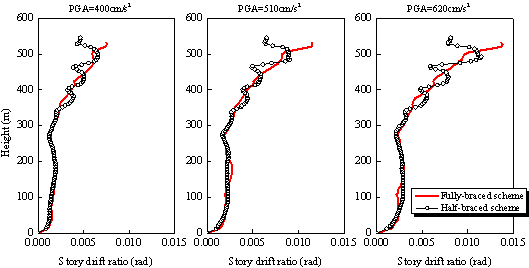

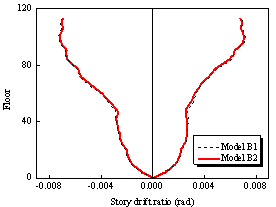

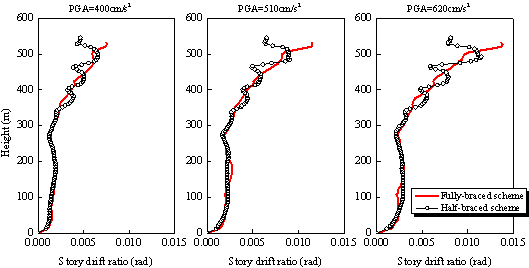

3.3 Seismic performance

Although

the fully-braced scheme is advantageous in material consumption, the seismic

performances and collapse resistances of these two design schemes need to

be further studied. The seismic performances of the two design schemes are

comprehensively compared through nonlinear time history analysis (THA) using

different ground motions at various intensities. The seismic responses of

the two schemes subjected to the widely used ground motion records, El-Centro

EW 1940, are illustrated herein as typical cases. The PGA of the El-Centro

EW 1940 ground motion record is scaled to 400 cm/s2, 510 cm/s2

and 620 cm/s2, which correspond to the MCE level ground motion

of the seismic design intensities of 8, 8.5 and 9 degrees, respectively, as

specified by the Chinese code (CMC, 2010a). The classical Rayleigh damping

is adopted with a damping ratio of 5% in the nonlinear THA. Note that the

design intensity of this building is 8 degree. However, given the special

functionality and importance of this supertall building, stronger ground motions

are considered as the seismic input for the structure to evaluate the performance

of the building subjected to extreme earthquakes. The envelopes of story drift

responses of the two schemes are shown in Figure 5.

Figure 5. The story drift responses

of the two design schemes

It indicates that the story drift ratio

in the lower four zones is uniform and has no significant difference between

the two design schemes. Meanwhile, the story drift ratio in the upper zones

of the fully-braced scheme is slightly smaller than that of the half-braced

scheme; and this trend increases with the increase of earthquake intensity.

At the top of the building, the story drift ratio of the fully-braced scheme

is larger than that of the half-braced scheme. This is because the top three

stories of the fully-braced scheme are the sightseeing region. Hence, fewer

lateral force resisting components are allowed in this region according to

the requirement of the architectural function. Correspondingly, the lateral

stiffness of this region is relatively smaller than that of the other zones.

In addition, the story drift ratio in the upper zones of the half-braced scheme

has significant reductions at the location of each circle belt truss. This

phenomenon is due to the arrangement of the outriggers between Zone 5 and

Zone 8, which significantly enhance the local structural stiffness and hence

decrease the story drift ratio.

Generally, the seismic responses at the

MCE level of the two design schemes are very similar and the nonlinear THA

does not distinguish one scheme better than the other. Hence, earthquake-induced

collapse analysis based on IDA is necessary to be performed to evaluate the

ultimate collapse resistance of the two design schemes.

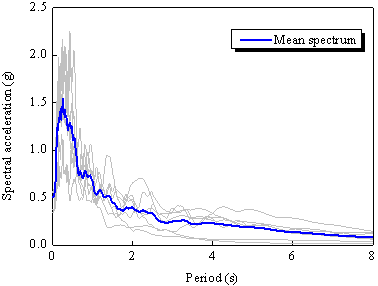

3.4 Collapse analysis

Due

to the absence of the site-specified ground motion records at the preliminary

design stage, the widely used 22 far-field ground motion records suggested

by FEMA P695 (2009) and the El-Centro EW 1940 ground motion are adopted as

the basic seismic input for the following two considerations.

(1) This work focuses on the relative

collapse capacity between the half-braced and fully-braced schemes in order

to identify the better design. For this reasion, the seismic input of these

two designs are kept the same, thereby the relative collapse capacities of

these two buildings can be obtained and differentiated; yet, the absolute

seismic performance of each design may not be as so accurate. Note that, at

the final design stage, a more accurate ground motion record set, which matches

the site-specified spectrum, has been adopted to further assess the seismic

performances of the improved designs.

(2) Although the 22 far-field ground

motion record set is primarily intended for buildings with natural (first-mode)

periods less than or equal to 4 seconds, FEMA P695 (2009) also indicates that

most records obtained from the newer seismographs are typically accurate to

at least 10 seconds. As such, most records in far-field and near-field record

sets are accurate to a period of at least 10 seconds. The fundamental periods

of the two buildings are 7.44 s and 7.38 s, which are within the range of

10 seconds. Hence, the reliability of the evaluated seismic performances by

22 far-field ground motion record set is considered acceptable at the preliminary

design stage.

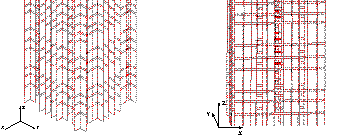

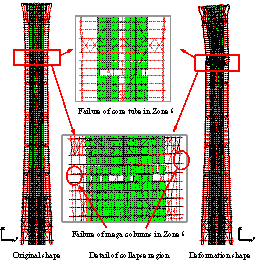

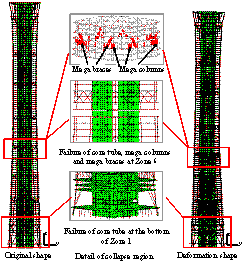

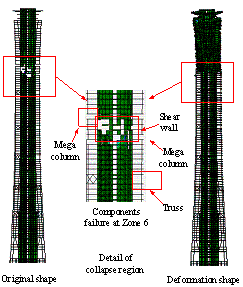

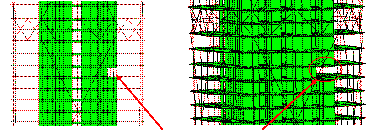

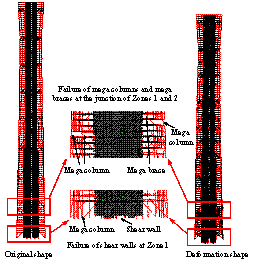

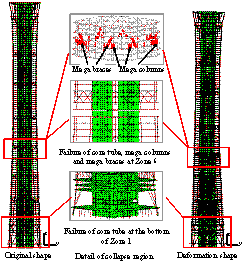

The earthquake-induced collapses of these

two design schemes subjected to extreme earthquakes are conducted using the

proposed method presented in Section 2.3. And a typical earthquake-induced

collapse process of the fully-braced scheme subjected to El-Centro EW 1940

ground motion with a PGA = 2058 cm/s2 is shown in Figure 6. At

the initial stage when t = 2.055 s (Figure 6(a)), the coupling beams

at the bottom of the core tube begin to fail due to shear. When t =

2.955 s (Figure 6(b)), the shear walls at Zone 6 begin to fail due to concrete

crushing. When t = 10.810 s (Figure 6(c)), as the shear walls at Zone

6 have already been damaged severely, the internal forces are redistributed

to other structural components. This results in gradually increased vertical

and horizontal loads in the mega columns. Subsequently, the mega columns at

the top of Zone 6 begin to fail due to the combined overturning moment and

compression. When t = 14.500 s (Figure 6(d)), the mega braces at Zone

6 begin to fail. When t = 15.360 s (Figure 6(e)), most of the core

tube, mega columns and mega braces are damaged in Zone 6 leading to the loss

of the vertical load carrying capacity of the building. Consequently, the

collapse of the whole building takes place. Meanwhile, large horizontal displacement

responses of the upper zones induce an additional overturning moment due to

the P-D

effect. From the collapse process described above, the progress of structural

failure generally follows: from the coupling beams at the bottom of the core

tube, to the shear walls at Zone 6, then to the mega columns at Zone 6, and

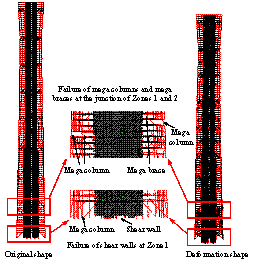

finally to the mega braces at Zones 6. In contrast, as discussed by

Lu et al. (2013a), a different pattern of the collapse process was found for

the half-braced scheme subjected to El-Centro EW 1940 ground motion, where collapse starts from the core tube at the bottom, then

to the shear walls and coupling beams in the higher zones, and finally

to the mega columns in Zones 1 and 2.

|

|

|

(a) t = 2.055 s, initiation of

failure of coupling beams at the bottom of core tube

|

|

|

|

(b) t = 2.955 s��failure of shear walls at Zone 6

|

|

|

|

(c) t = 10.810 s��failure of mega columns at Zone 6

|

|

|

|

(d) t = 14.500 s��failure of mega braces at Zone 6

|

|

|

|

(e) t = 15.360 s, most of the core

tube, mega columns and mega braces are damaged at Zone 6

|

|

Figure

6 Collapse details of fully-braced scheme subjected to El-Centro

EW (PGA = 2058

cm/s2)

|

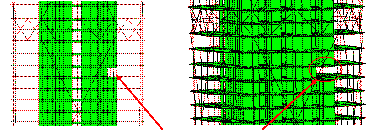

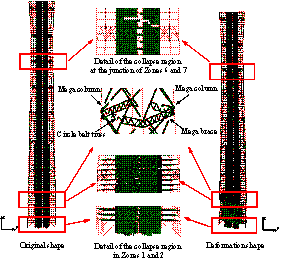

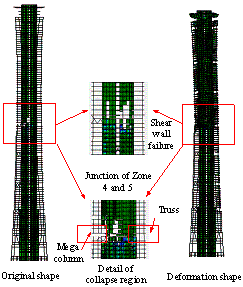

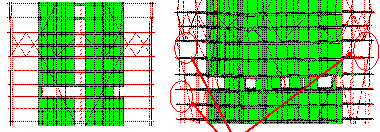

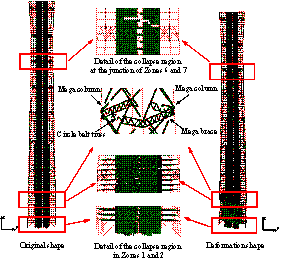

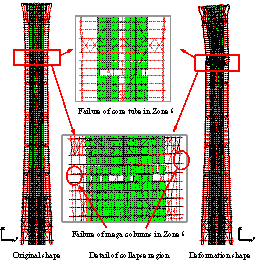

The collapse modes of the two schemes

subjected to the ground motion of El-Centro EW 1940 are compared in Figure

7. It clearly shows that the initial collapse region of the half-braced scheme

occurs at the bottom of Zone 2. In addition, the junction of Zones 6 and 7

also exhibit severe damage. In contrast, the earthquake-induced collapse of

the fully-braced scheme begins at Zone 6.

|

El-Centro EW (PGA = 2940

cm/s2)

|

KOBE_SHI000 (PGA

= 1764 cm/s2)

|

|

(a) Half-braced scheme

|

|

El-Centro EW (PGA

= 2058 cm/s2)

|

KOBE_SHI000 (PGA

= 2058 cm/s2)

|

|

(b) Fully-braced scheme

|

Figure 7. Typical collapse modes

of the two design schemes subjected to extreme earthquakes

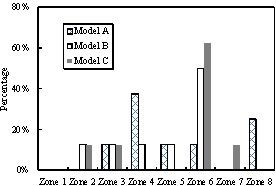

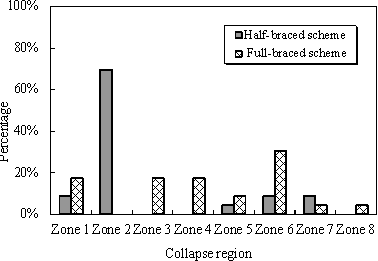

Giving the randomness nature of earthquakes,

different failure modes may be triggered by different ground motions. The

collapse mode of the fully-braced scheme subjected to KOBE_SHI000 ground motion

is also shown in Figure 7. The collapse progresses as follows: failure is

initiated from the coupling beams at the bottom of the core tube, then to

the shear walls at Zone 3, subsequently to the mega columns at Zone 3, and

finally to the mega braces at Zone 3, which is followed by the collapse of

the entire structure. However, as described by Lu et al. (2013a), the collapse

process of the half-braced scheme subjected to KOBE_SHI000 ground motion starts

from the failure of shear walls at the bottom of the building. Subsequently,

the mega columns and shear walls at Zone 2 are severely damaged. All these

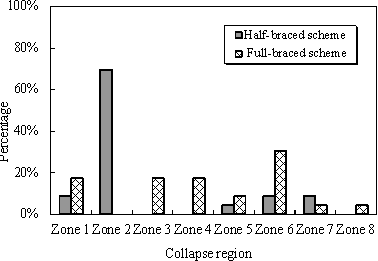

failures lead to the collapse of the entire building. The initial collapse

regions of these two schemes subjected to the 23 ground motion records are

shown in Figure 8. It is evident that Zone 2 is the main collapse region for

the half-braced scheme and it accounts for approximately 69.57% of all the

potential collapse regions. In contrast, the initial collapse regions of the

fully-braced scheme are more uniformly distributed in each zone. Zone 6, which

has the smallest planar layout, has a higher possibility to become the initial

collapse region than the other zones. Such initial collapse regions can also

be treated as the weakest points of the building when performing design optimization

of the structural components.

Figure 8 Collapse regions of

the two design schemes

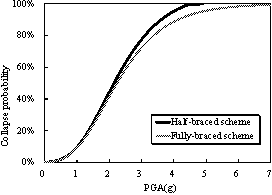

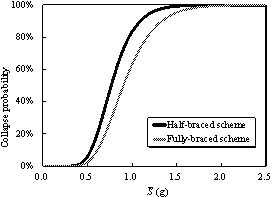

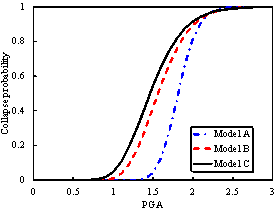

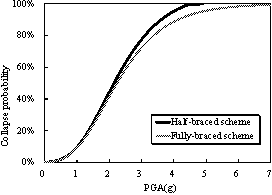

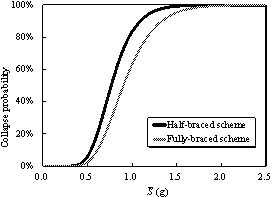

The collapse fragility curves for these

two schemes are compared in Figure 9. Because of the complicated nature of

ground motion records, the intensity measure (IM) may affect the shape

of the fragility curves. The authors have previously discussed the rationality

of different IMs for supertall buildings and proposed a more efficient

IM as shown in Eq.(1) (Lu et al, 2013c,d).

|

, ,

|

(1)

|

where Sa(Ti) is the spectral acceleration

for the ith period; n is the number of the translational

vibration modes to be considered;  reflects the geometric mean of the spectral

acceleration at the first n periods of the structure, which contributes

the most to the structural seismic responses. The collapse fragility curves

for the two design schemes using PGA and reflects the geometric mean of the spectral

acceleration at the first n periods of the structure, which contributes

the most to the structural seismic responses. The collapse fragility curves

for the two design schemes using PGA and  as IMs are shown in Figure 9. Generally,

the collapse probability of the half-braced scheme is higher than that of

the fully-braced scheme subjected to the same ground motion intensity. The

dispersions of the fragility curves based on as IMs are shown in Figure 9. Generally,

the collapse probability of the half-braced scheme is higher than that of

the fully-braced scheme subjected to the same ground motion intensity. The

dispersions of the fragility curves based on  (Figure 9(b)) are significantly smaller

than those based on PGA (Figure 9(a)). For example, the IM of each

ground motion that triggers a collapse is recorded, which is referred to as

��IMcollapse�� (e.g., ��PGAcollapse �� or �� (Figure 9(b)) are significantly smaller

than those based on PGA (Figure 9(a)). For example, the IM of each

ground motion that triggers a collapse is recorded, which is referred to as

��IMcollapse�� (e.g., ��PGAcollapse �� or ��

��). The coefficient of variation (COV) of PGAcollapse

for the half-braced scheme is 0.426. In contrast, the corresponding COV of ��). The coefficient of variation (COV) of PGAcollapse

for the half-braced scheme is 0.426. In contrast, the corresponding COV of

is only 0.282. Thus, is only 0.282. Thus,  is able to significantly reduce the dispersion

of collapse resistances due to different ground motions. It

should be noted that the Chinese building code adopts PGA to quantify the

earthquake intensity, which is also popularly used in engineering practices.

Note also that although different IMs will affect the dispersion of

collapse resistances, they will not necessarily affect the relative collapse

resistances of different design schemes. Therefore, PGA is selected as the

IM to facilitate the following discussion in this work. is able to significantly reduce the dispersion

of collapse resistances due to different ground motions. It

should be noted that the Chinese building code adopts PGA to quantify the

earthquake intensity, which is also popularly used in engineering practices.

Note also that although different IMs will affect the dispersion of

collapse resistances, they will not necessarily affect the relative collapse

resistances of different design schemes. Therefore, PGA is selected as the

IM to facilitate the following discussion in this work.

|

|

|

|

(a) Based on PGA

|

(b) Based on

|

|

Figure 9. The collapse

fragility curves for the two design schemes

|

The CMR proposed in FEMA P695

(2009) is adopted to quantify the structural collapse resistance capacity,

which is defined by the following equation.

|

|

(2)

|

where,

IMCT is the ground motion intensity subject to which the

collapse possibility is 50%; IMMT is the ground motion intensity

corresponding to the design MCE level. For both design schemes, the PGA corresponding

to the MCE level is 0.4 g as specified in the design code, and the PGAs inducing

a 50% of the building collapse are 2.35 g and 2.70 g, respectively, for the

half- and fully-braced schemes. Consequently, the CMRs of the two schemes

are 5.88 and 6.75, respectively, according to Eq. (2). This evidently demonstrates

that the fully-braced scheme has a relatively higher collapse resistance than

the half-braced scheme.

According to FEMA P695 (2009), the total

system collapse uncertainty (bTOT) considered

in this work is estimated to be 0.675. Thus, the CMR corresponding

to a 5% collapse possibility at MCE level is 3.04 (FEMA P695 2009). Both the

CMRs of the two design schemes readily meet this requirement. It is

noteworthy that these CMRs don��t account for the expected epsilon (e) for the building site

and collapse hazard intensity. To slove this issuse, Haselton et al, (2011)

and FEMA P695 (2009) suggested a simplified spectral shape factors (SSF)

to get a more accurate CMR prediction (ACMR=SSF��CMR, where

ACMR is the adjusted collapse margin ratio). SSF depends

on the building dynamic characteristics, inelastic performances and e parameters. Given that

the e parameters are not provided

in the seismic hazard map of China, it becomes problematic to compute the

SSF and ACMR. Note that this work focuses on the relative collapse

capacity between the half-braced and fully-braced design schemes. As the locations

of the two buildings have the same site conditions, and both buildings have

similar vibration periods, their SSF values are expected to be very

close. Thus, the unadjusted collapse margin ratio can still be used to distinguish

which design is a better one.

Furthermore, the collapse probabilities

of these two buildings at the MCE level earthquake are approximately 1.34%

and 1.29%, respectively,

for half-braced and fully-braced schemes. Clearly, such low collapse probabilities

also meet the requirements of both ASCE 7-10 (i.e., < 6% at the MCE level

for Risk Category III) (ASCE, 2010) and the Code for anti-collapse design

of building structures of China (i.e., < 5% at the MCE level)

(CAECS, 2015). Note that the fully-braced scheme exhibits a higher collapse

resistance, having a CMR 14.8% higher than that of the half-braced

scheme. Furthermore, the total material consumption of the fully-braced scheme

is 11.2% lower than that of the half-braced scheme. As a result, the fully-braced

scheme is suggested as the lateral force resisting system for the supertall

building studied herein.

|